Locations and subsidiaries

Innovation and highest quality standards

ROCO relies on the highest quality and craftsmanship. The combination of high engineering expertise and the precise work of qualified employees characterizes Roco’s models as being true to the originals. More than 900 qualified employees contribute to the success of the ROCO brand and operate at five sites.

Headquarters Bergheim/Salzburg (Austria)

The company headquarters is established in Bergheim near Salzburg. In addition to the management, the globally active sales and marketing staff, the product management and all commercial departments as well as the central customer service of the company are located in the headquarters. There is also a small shop with selected items at this location, which you are welcome to visit during the following opening hours: Monday to Thursday: 09:00 to 15:00 and Friday 09:00 to 12:00.

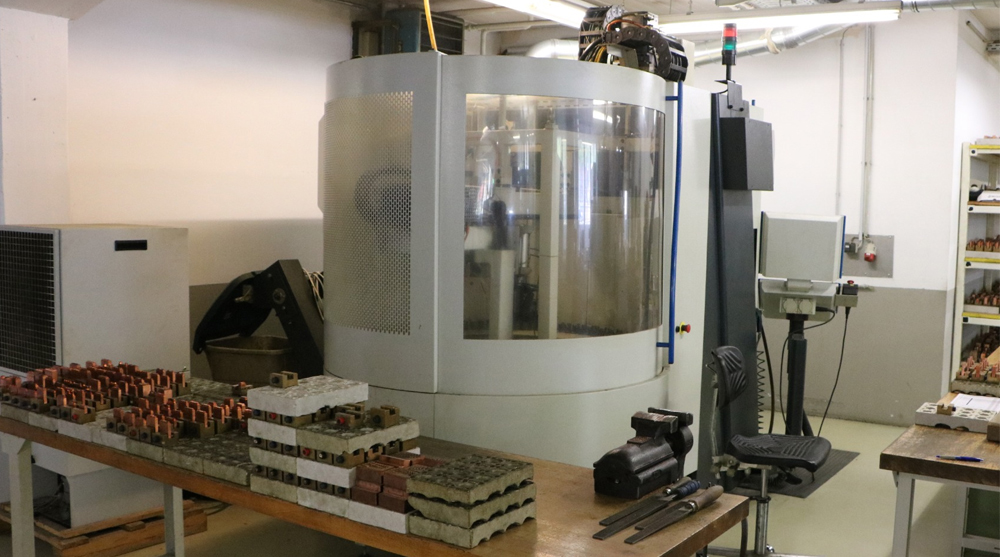

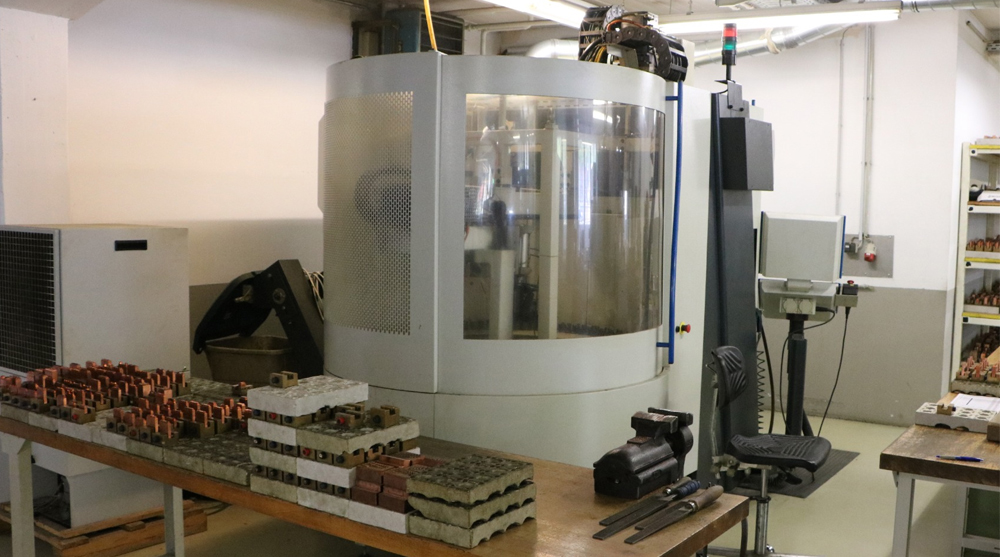

Technikum (technical centre) in Gloggnitz (Austria)

The company-wide development centre of Modelleisenbahn GmbH is located in Gloggnitz, Lower Austria. In addition to the design departments, the tool construction department is located here, where the majority of the company’s own high-precision injection moulds are produced. The location is rounded off by a plastic injection moulding technical centre, in which the newly-created injection moulds are further developed until they are ready for series production and in which the injection moulding production of first series also takes place.

Production plant in Banská Bystrica (Slovakia)

The Slovakian town of Banská Bystrica is home to the group's most universal plant in terms of its range of tasks. The main location in Banská Bystrica is home to the competence centre for surface finishing, the central production logistics hub and various assembly departments. The surface departments include a paint shop, a large pad printing department with highly functional multi-colour presses and a digital printing department that has become a leader in the industry due to years of research and development. In addition to the surface departments, electric motors for the locomotives are also manufactured at the site, as well as part of the extensive range of rails and accessories using special machines. Metal injection moulding is also located in Banská Bystrica.

The location is complemented by a second smaller production plant north of Banská Bystrica, where a large part of the plastic injection moulding series production, the rail production and the stamping shop are located.

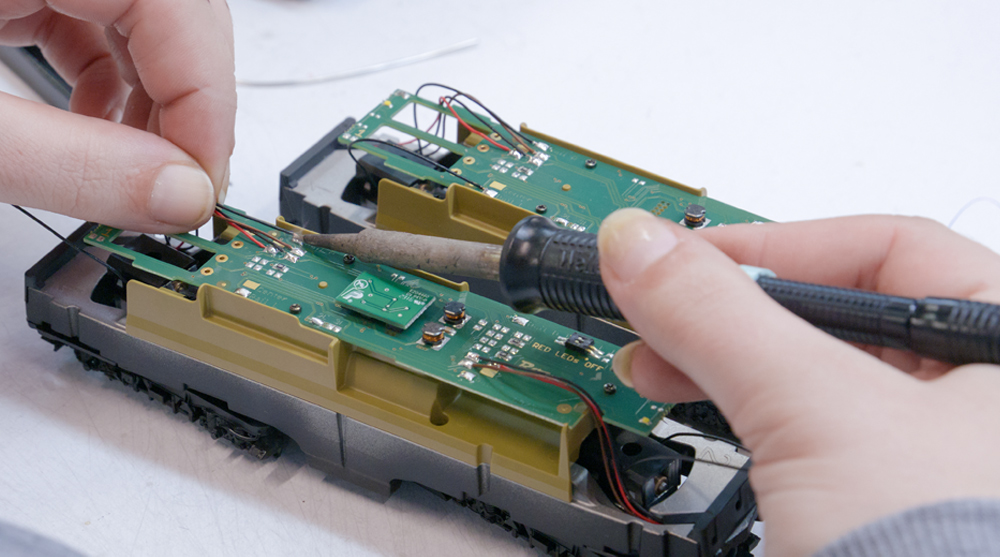

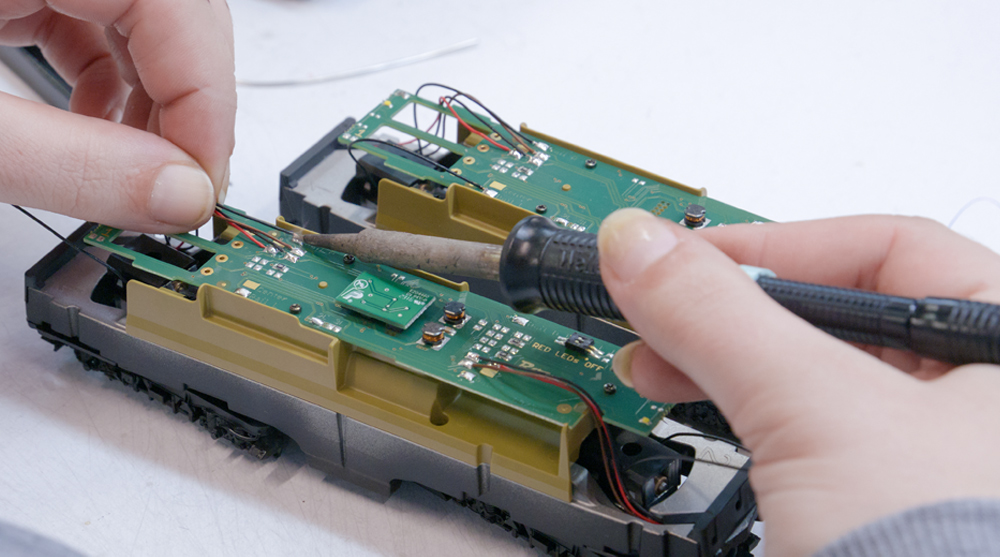

Production plant in Arad (Romania)

At the plant in the Romanian city of Arad, the complete final assembly of the locomotives, wagons, rails and accessory components manufactured in Europe takes place. Here, the beautiful locomotives and wagons for which the ROCO and FLEISCHMANN brands are known are completed from several hundred parts.

The company-wide spare parts warehouse with approx. 50,000 different spare parts is also located at the Arad site, as well as the repair departments for complaints and repairs.

Production plant in Ho Chi Minh City (Vietnam)

The most recent factory is located in Ho Chi Minh City, a city of millions in the economic centre of Vietnam. Since the end of 2016, a large number of complete models have been produced in this plant, from plastic injection moulding to painting, printing and final assembly. The miniature models go through the same production steps as in Europe, which also ensures a consistently high model and quality standard of the model railways worldwide.